Velox Boiler – Construction, Working Principle and Advantages:

Velox Boiler – When the gas velocity exceeds the sound velocity, the heat is transferred from the gas at much higher rates than rates achieved with sub-sonic flow. This advantage is used to utilize the large heat transfer from a smaller surface area in this boiler.

Construction of Velox Boiler:

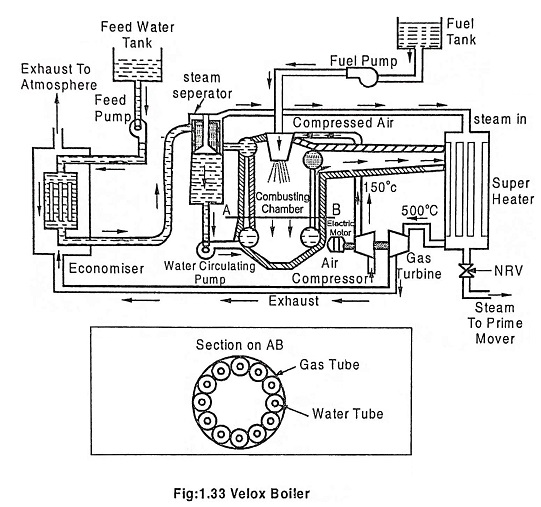

The arrangement is as shown in Fig. 1.33.

Working Principle:

Air is compressed from air compressor in the range of 2.5 bar, before supplying to the combustion chamber to get the supersonic flow of the gases passing through the combustion chamber and gas tubes. From the combustion chamber, the burnt gases are passed through the annulus of the tubes. The heat is transferred from gases to water while passing through the annulus to generate the steam. Water steam mixture is formed and it is entered in the form of spiral flow. Due to the centrifugal force, the heavier water particles are thrown outward on the walls. This is used to separate the steam from water.

The separated steam is further passed to superheater and then supplied to the prime mover. The water removed from the steam in the separator is again used into the water tubes with the help of a pump.

The gases coming out from the annulus is passed over the super heater where its heat is used for superheating the steam. The gases are used to run the gas turbine as they carry sufficient kinetic energy. The power output of the gas turbine is used to run a gas turbine. The exhaust gases coming out from the gas turbine are passed through the economizer to utilize the remaining heat of the gases.

The electric motor is used to supply the extra power required to run the compressor.

Capacity of Velox boiler: 100 tons/hr.

Advantages:

- The combustion rate is more.

- It is more compact.

- It has greater flexibility.

- It can be quickly started even though the separator has a storage capacity of about 10% of the maximum hourly output.