What is Bearing? – Definition and Types of Bearings:

Bearings are those parts of a machine which house supports and restrain the rotating parts. The moving part of the bearing is known as journal and the stationary part that supports the moving part is known as bearing.

The main functions of a bearing, besides supporting the rotating parts, are (i) to permit free rotation of the moving components with minimum friction and (ii) to maintain the rotating member of the machine in a fixed physical location relative to the stationary member.

The bearings are of two types, namely (i) ball or roller bearings and (ii) sleeve or bush bearings.

1. Ball Bearing or Roller Bearings

Ball or roller bearings are those bearings in which shafts are supported by balls or rollers which themselves are movable. The action in ball or roller bearings is not that of rubbing but of rolling between the balls and or rollers and their races, the inner surface being fixed to the shaft while the outer surface is fixed to the housing supporting the bearing. Such bearings are supplied and filled with grease. The period between the renewal of grease depends upon the speed of rotation of the motor. These are also known as antifriction bearings.

Up to about 75 kW use of ball or roller bearings is made. Very small motors are usually provided with ball bearings. In vertical shaft drives the ball bearings are essential as they are capable of taking an axial thrust.

Though the initial cost of bearings of this type is high but their life is longer, occupy less space, friction loss is smaller and their maintenance cost is low. These have made use of induction motors with small air gap possible as the roller bearing does not wear appreciably. However, these cannot be recommended where noise is to be avoided.

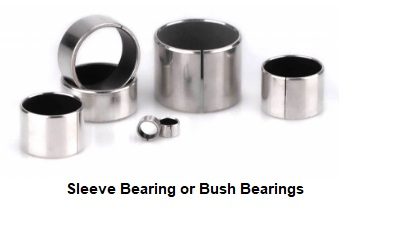

2. Sleeve Bearing or Bush Bearings

Sleeve or bush bearings are those bearings in which the rotating shaft is supported by a bearing component rigidly fixed to the frame of the machine. They may be (i) journal bearing offering support to the shafts at right angles to the shaft axes (ii) foot-step bearings supporting shafts parallel to the shaft axes and (iii) thrust or collar bearings offering support to shafts subjected to end or axial thrust.

Sleeve bearings are normally of bronze but for universal and fan-cooled motors, sintered powder or porous metal bearings may be used because of their self lubricating properties due to capillary action.

Sleeve bearings on very small motors are lubricated with an oil wick pressed lightly against the shaft by a spring. The wick must be kept saturated with a fairly light oil and will remain moist through several weeks of heavy use. Large sleeve bearings are ring lubricated which consists of a ring freely rotating on the shaft, carrying oil to the bearings. Lubricating oil, which is free from acid and resin, is renewed every six months. Temperature of bearing (either sleeve or roller) is the indication of the bearing condition. ISS 325 provides for maximum temperature rise at sleeve or ball bearings to be 50°C.

Bearings of this type are necessary to reduce the noise level for certain types of couplings and for the positions subject to external vibrations. They are also used where there is a danger of individual balls or rollers indenting the race during long rest periods.

Motors with sleeve bearings should always be used with shaft horizontal and fixed coupling between motor and the driven machine. Because of larger wear of the bearings, relatively large air gap in the induction motor has to be introduced.