What is Secondary Emission?

When a beam of high velocity electrons suddenly strikes a metallic surface, they give up their kinetic energy to electrons and atoms which they strike. Some of the bombarding electrons, called the primary electrons, collide directly with free electrons on the metal surface, and may knock them out from the surface, similar to billiard ball collision. Such an emission of electrons is called the secondary emission and the electrons emitted in this way are called the secondary electrons.

The number of secondary electrons that are emitted from a material, either a metal or a dielectric, when subjected to electron bombardment has been found experimentally to depend upon

- the number of primary electrons

- the energy of the primary electrons

- the angle of incidence of the electrons at the surface

- the type of emitting material and

- the physical condition of the surface

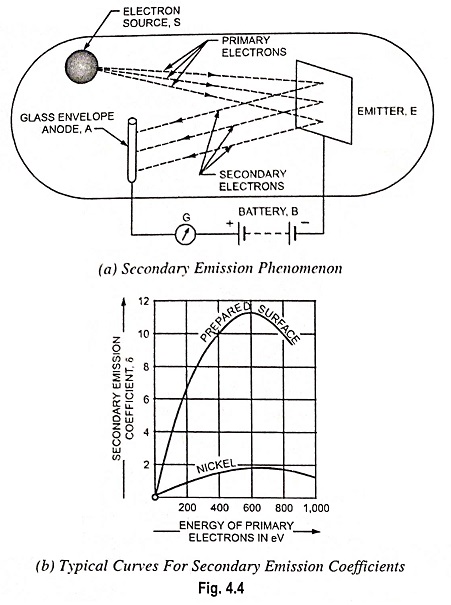

The phenomenon of secondary emissions is illustrated in Fig. 4.4 (a). An evacuated glass envelope contains emitter E, collecting anode A and a source of primary electrons. The anode A is made positive w.r.t. the emitter E by battery B. When the electrons emitted by electron source S, called the primary electrons, strike the emitting surface E at a high speed, they knock out electrons from the emitting surface, called the secondary electrons. These secondary electrons are attracted toward the anode and thus constitute a flow of current in the external circuit.

The intensity of the secondary emission, in a particular case, is explained by the “secondary emission coefficient” which is equal to the average number of secondary electrons emitted per primary electron striking the surface and is given by the symbol δ. Surface condition, as well as low work function, is important in materials for secondary emissions. The secondary emission coefficient for clean metals is usually very small for primary velocities corresponding to a few volts, rises to a flat maximum of between 1 and 2 for velocities corresponding to a few hundred volts, and decreases slowly for higher velocities. The yield or secondary emission coefficient δ is increased markedly by the presence of a contaminating layer of gas or by the presence of electropositive or alkali metal on the surface. For such composite surfaces, secondary emission coefficients as high as 10 or 15 have been detected. In case of insulating surfaces the secondary emissions does occur but coefficient is less than unity. Most secondary electrons are emitted with small (less than 3 eV) energies.

Typical curves for secondary emission coefficients are given in Fig. 4.4 (b).

Although the secondary emissions is an accidental phenomenon and often considered undesirable in certain electron devices, it is used to advantage in many electron devices e.g., cathode-ray tubes, electron multiplier tubes, dynatron oscillators, storage tubes in radar and electronic computers etc.

Secondary emission, no doubt, does not affect the operation of diode but certainly affects the operation of vacuum tubes having more than two electrodes. In fact secondary emissions is responsible for the -ve resistance characteristic of a tetrode.