Working Principle of Hydroelectric Power Plant:

The oldest and cheapest method of Working Principle of Hydroelectric Power Plant is that of utilizing the potential energy of water. The energy is obtained almost free of running cost and is completely pollution free. Of course, it involves high capital cost because of the heavy civil engineering construction works involved. Also it requires a long gestation period of about five to eight years as compared to four to six years for steam plants.

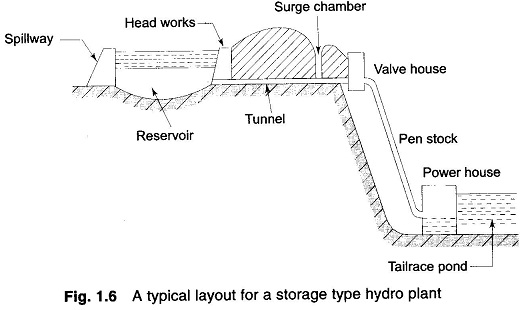

Working Principle of Hydroelectric Power Plant are designed, mostly, as multipurpose projects such as river flood control, storage of irrigation and drinking water, and navigation. A simple block diagram of a hydro plant is given in Fig. 1.6. The vertical difference between the upper reservoir and tail race is called the head.

Hydro plants are of different types such as run-of-river (use of water as it comes), pondage (medium head) type, and reservoir (high head) type. The reservoir type plants are the ones which are employed for bulk Hydroelectric Power Generation. Often, cascaded plants are also constructed, i.e., on the same water stream where the discharge of one plant becomes the inflow of a downstream plant.

The utilization of energy in tidal flows in channels has long been the subject of research. The technical and economic difficulties still prevail. Some of the major sites under investigation are: Bhavnagar, Navalakhi (Kutch), Diamond Harbour and Ganga Sagar. The basin in Kandala (Gujrat) has been estimated to have a capacity of 600 MW. There are of course intense siting problems of the basin. Total potential is around 9000 MW out of which 900 MW is being planned.

A tidal power station has been constructed on the La Rance estuary in northern France where the tidal height range is 9.2 m and the tidal flow is estimated to be 18,000 m3/sec. –

Different types of turbines such as Pelton, Francis and Kaplan are used for storage, pondage and run-of-river plants, respectively. Hydroelectric plants are capable of starting quickly—almost in five minutes. The rate of vking up load on the machines is of the order of 20 MW/min. Further, no losses are incurred at standstill. Thus, hydro plants are ideal for meeting peak loads. The time from start up to the actual connection to the grid can be as short as 2 min.

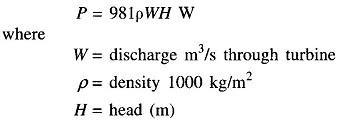

The power available from a hydro plant is

Problems peculiar to hydro plant which inhibit expansion are:

- Silting reportedly Bhakra dead storage has silted fully in 30 years

- Seepage

- Ecological damage to region

- Displacement of human habitation from areas behind the dam which will fill up and become a lake.

- These cannot provide base load, must be used for peak shaving and energy saving in coordination with thermal plants.

India also has a tremendous potential (5000 MW) of having large number of micro (< 1 MW), mini (< 1-5 MW), and small (< 15 MW) hydel plants in Himalayan region, Himachal, UP, Uttaranchal and JK which must be fully exploited to generate cheap and clean power for villages situated far away from the grid power.

At present 500 MW capacity is under construction. In areas where sufficient hydro generation is not available, peak load may be handled by means of pumped storage. This consists of an upper and lower reservoirs and reversible turbine-generator sets, which can also be used as motor-pump sets.

The upper reservoir has enough storage for about six hours of full load generation. Such a plant acts as a conventional hydro plant during the peak load period, when production costs are the highest. The turbines are driven by water from the upper reservoir in the usual manner. During the light load period, water in the lower reservoir is pumped back into the upper one so as to be ready for use in the next cycle of the peak load period. The generators in this period change to synchronous motor action and drive the turbines which now work as pumps.

The electric power is supplied to the sets from the general power network or adjoining thermal plant. The overall efficiency of the sets is normally as high as 60-70%. The pumped storage scheme, in fact, is analogous to the charging and discharging of a battery. It has the advantage that the synchronous machines can be used as synchronous condensers for VAR compensation of the power network, if required. In a way, from the point of view of the thermal sector of the system, the pumped storage scheme “shaves the peaks” and “fills the troughs” of the daily load demand curve.

Some of the existing pumped storage plants are 300 MW Srisailem in AP and 80 MW at Bhira in Maharashtra.