Working Principle of Linear Induction Motor:

While the conventional induction motor gives rotary motion, a Working Principle of Linear Induction Motor provides translational or linear motion. Hence it is termed linear induction motor.

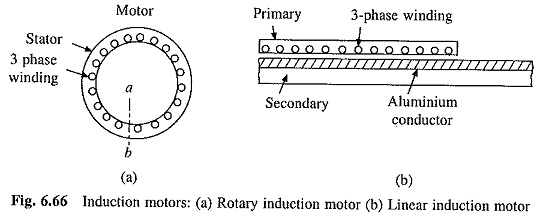

To understand the principle of operation let us examine stator of the rotary induction motor (Fig. 6.66(a)). Let the stator be cut and unrolled (Fig. 6.66(b)). This forms primary of the Working Principle of Linear Induction Motor. Secondary of the linear induction motor consists of a flat aluminium conductor with a ferromagnetic core.

If a three-phase supply is connected to the stator of a rotary induction motor, a flux wave, which rotates at a synchronous speed in the air gap, is produced. Similarly, if primary of the linear induction motor is connected to a three-phase supply, a flux wave travelling along the length of primary will be produced. Due to the relative motion between travelling flux wave and aluminium conductor, current is induced in the aluminium conductor.

The induced current interacts with travelling flux wave to produce translational force F. If secondary is fixed and primary is free to move, the force will make primary to move in the direction of travelling wave. In order to maintain the motion, the secondary has to be laid out along the whole length primary is required to move.

Types of Linear Induction Motor:

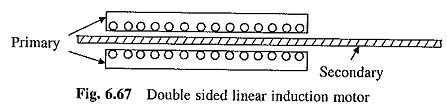

The linear induction motor of Fig. 6.66(b) is known as Single Sided Linear Induction Motor. Double Sided Linear Induction Motor is shown in Fig. 6.67. It has primaries on both sides of the secondary. The speed torque characteristic of these linear motors is similar to that of rotary induction motor (Fig. 6.2).

As compared to rotary induction motor, the linear requires a larger air-gap. Consequently, the magnetizing current is large, and therefore, power factor and efficiency are low.

Application of Linear Induction Motor:

The main application of linear induction motor is in transportation, including electric traction. Primary is mounted on the vehicle and secondary laid along the track. As in rotary induction motor, variable frequency control is employed for starting, speed control and braking. The Working Principle of Linear Induction Motor has also been employed for material handling, pumping of liquid metal and sliding door closures.